Budget discrepancies, unclear specifications, and file setup issues. These are just a few things that can cause your next print project to go off course.

Thankfully, with the right print partner, setbacks like these can be overcome fairly quickly and hopefully with minimal budgetary impact. Even if substantial issues arise, your printer may be able to suggest alternative production options that will get the project back on track.

The larger problem, however, is that print production is typically the last step in a creative marketing project. Therefore issues at this stage can lead to critical project failures—no matter how well your printer course corrects.

So what can you do to eliminate issues before they happen? Here are some tips to help marketers and designers avoid costly errors and delays on their next print project.

Communicate the Whole Picture to Your Printer

Good communication is the key to successful creative projects, especially if they include a print or direct mail component. Since every print project has unique requirements and a group (sometimes large) of internal and external stakeholders, solid communication is critical.

When kicking off a project with your printer it may be tempting to jump immediately into the creative details or technical features. For example, you might begin by asking to “create a really cool box”. That’s great because printers love making cool things. However, if the box can’t get to the recipient because it wasn’t constructed with mailing in mind, the project will come to a screeching halt.

To avoid similar situations tell your printer what you aim to achieve before discussing details and specs. Whenever possible share your metrics and ROI goals so your print partner can steer you towards production techniques that align with the value of your desired outcome (i.e. product sale, event registration, etc.). When printers understand the whole picture they can make better recommendations and help you avoid issues down the road.

Develop Clear Specifications

Once everyone fully understands the project goals, it is time to develop specifications. Incorrect specs can lead to print estimates that are either too low or too high—delaying a project from the start. When an estimate is too low you risk losing budget dollars that were earmarked for specific departments or projects. Or if the estimate is too high you may have to wait for additional funds or unnecessarily cut back on quantity or design features.

Don’t Rely on Physical Samples Alone

Physical samples can be a great tool, but they shouldn’t be a replacement for specifications. Without specs, printers can only make assumptions about the way a project was previously produced. And because every printer’s equipment and processes are different relying only on those assumptions could result in issues as the production process rolls on. If you’re not sure how a project was produced review the physical sample with your printer and develop a list of specs that everyone is in agreement with before proceeding.

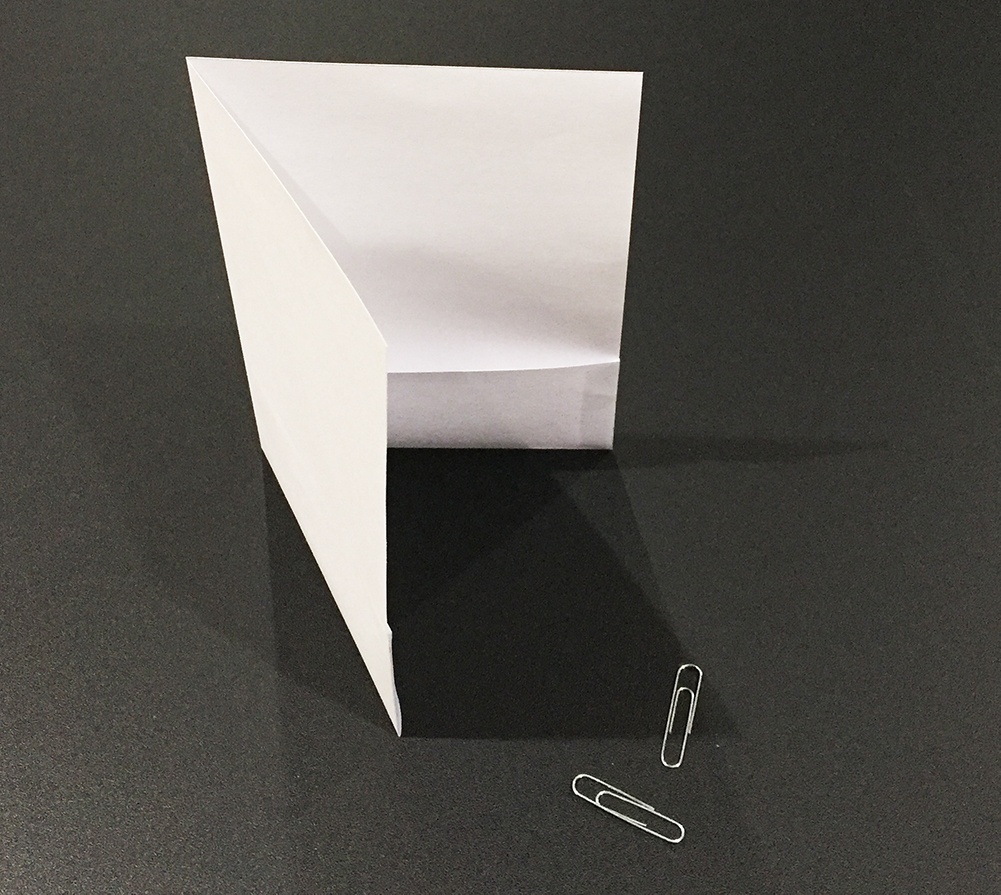

Request a Mock-up or Stock Dummy

If your print or direct mail project is dimensional or includes a unique fold or die-cut, it’s a good idea to request a mock-up or stock dummy. This is a great way to identify any issues and ensure that everyone is on the same page before production begins. Although a mock-up or stock dummy (produced using the specified paper stock) can add a day or two to the project, that is a small price to pay in order to avoid more costly issues later.

Shawmut's design team loves the "mini-mockup" which can help identify issues early-on. Simply print your dieline or design with your office printer and fold it to create a miniature example of your project.

Shawmut's design team loves the "mini-mockup" which can help identify issues early-on. Simply print your dieline or design with your office printer and fold it to create a miniature example of your project.

Share or Clearly Describe Your Artwork

Some print techniques aren’t suited for every type of design. For example, if you want to produce a 4-color envelope there is a big difference between incorporating a logo or a full-color image with bleeds. Although both options specify a 4-color envelope, an image that extends to the edge will require the envelope to be converted—a process that can significantly increase costs and production time. Other design elements that may not align well to specs include heavy ink coverage, gradients, and specialty coatings, to name a few.

This envelope for Agri-Mark features a one-color (black and white) background image, which was designed with edge margins so the envelope didn't need to be converted.

This envelope for Agri-Mark features a one-color (black and white) background image, which was designed with edge margins so the envelope didn't need to be converted.

Sharing artwork with your printer—even during draft stages—will identify red flags that need to be addressed before production.

Carefully Coordinate Internal Artwork Approvals Before Submitting

Layout and text edits after artwork is sent to a printer is one of the most common causes of delays. In addition, if files print files aren’t properly prepared the project can be held up in prepress. These types of issues can eat through press time and lead to AA charges from printers. To avoid this, make sure internal teams have carefully reviewed and approved all artwork before it gets to the printer. Whenever possible work with experienced print designers or ask for file prep guidelines to ensure that your project is set up for success.

Provide Clean Data and Clear Mailing Instructions

Messy data and last minute mailing lists can result in wasted postage which accounts for a significant percentage of direct mail budgets. That’s why it is important to collect your data early on in the process. Printers need time to process mail lists during which invalid addresses will be identified and removed. In some cases, this can lead to a substantial decrease in the final mail quantity and waste if production had already begun.

Providing data files early along with clear mailing instructions is also critical for projects that include segmentation and personalization. Depending on how the data will be used, it could take days or even weeks to process your file and prepare it for variable data printing.

Leave Nothing Unchecked on Your Proof

Once you receive the proof from your printer make sure it is carefully reviewed by the designer, manager, end client, and any other project stakeholders. Identify which team members will need to review proofs for color and ensure that they have access to identical sets of hard copy proofs at the same time. If those individuals will be reviewing color during a press check ensure that everyone is present and on-time. If press checks and proof approvals—whether hard copy or digital—take longer than expected it can lead to downtime at the printer, less time for production (which can lead to errors), rush charges, and changes in production schedules. All of these issues can delay your project or result in additional costs.

Although every print project is unique, being aware of these common pitfalls can help you avoid errors and delays. The key is to communicate with your printer early and often. And if you’re not sure about a specific type of printing process or technique, ask your printer or set up a tour. That’s a great way to prepare for your next print project and ensure everything goes according to plan.